Urban Green and Low Carbon Scenario Demonstration Base 2025

2025 Urban Green and Low Carbon

Scenario Demonstration Base

01. Lianhua Mountain Supercharging Station

Project Location and Technology

● Located beside Kaifeng Community Park in Futian District, Shenzhen, the project covers an area of 3,192 square meters and serves as China's first demonstration station integrating multiple advanced technologies, including "solar-storage-ultra-fast charging + vehicle-to-grid interaction + Power HarmonyOS + Power Cube" systems. It is also Shenzhen's only five-star charging station and the largest vehicle-to-grid (V2G) demonstration site in the Guangdong–Hong Kong–Macao Greater Bay Area.

● The station features 27 charging piles and 46 charging guns, with power capacities ranging from 60 kW to 600 kW. It is equipped with a 4,100 kVA transformer system, 180 kWp photovoltaic installation, 200 kWh energy storage system, and a 2,160 kW V2G interaction capacity.

● A new prefabricated near-zero-carbon landscape power distribution unit ("Power Cube") is deployed, integrating prefabricated cabins, standardized ring main units, transformers, low-voltage switchgear, and sensors. This enables factory prefabrication, structured production, and one-piece modular assembly, creating a highly efficient and low-carbon power infrastructure.

Technical Advantages and Achievements

● The project pioneers a multi-functional charging hub integrating "solar-storage-ultra-fast charging + vehicle-to-grid interaction + Power HarmonyOS + Power Cube" technologies. Built on the Power HarmonyOS platform, it unifies substations, distribution systems, photovoltaics, energy storage, Power Cubes, and high-power charging into a single "multi-station-in-one" system. The Power HarmonyOS system enables full domestic localization of charging pile operating systems and supports bidirectional interaction between electric vehicles and the power grid, with a V2G capacity of 2,160 kW—the largest in the Guangdong–Hong Kong–Macao Greater Bay Area — significantly improving energy utilization efficiency.

● The Power Cube, based on prefabricated cabin technology, offers high prefabrication levels, short construction cycles, compact footprint, and low investment cost, while featuring a modern design that harmonizes with the urban environment.

● The station serves over 250,000 new energy vehicles annually, with a daily peak charging capacity exceeding 20,000 kWh and an annual charging volume of more than 7 million kWh. Its photovoltaic system generates approximately 180,000 kWh of electricity per year, reducing carbon emissions by about 120 tons, while the energy storage system provides an annual peak-shaving capacity exceeding 150,000 kWh, strengthening the stability of the regional power grid.

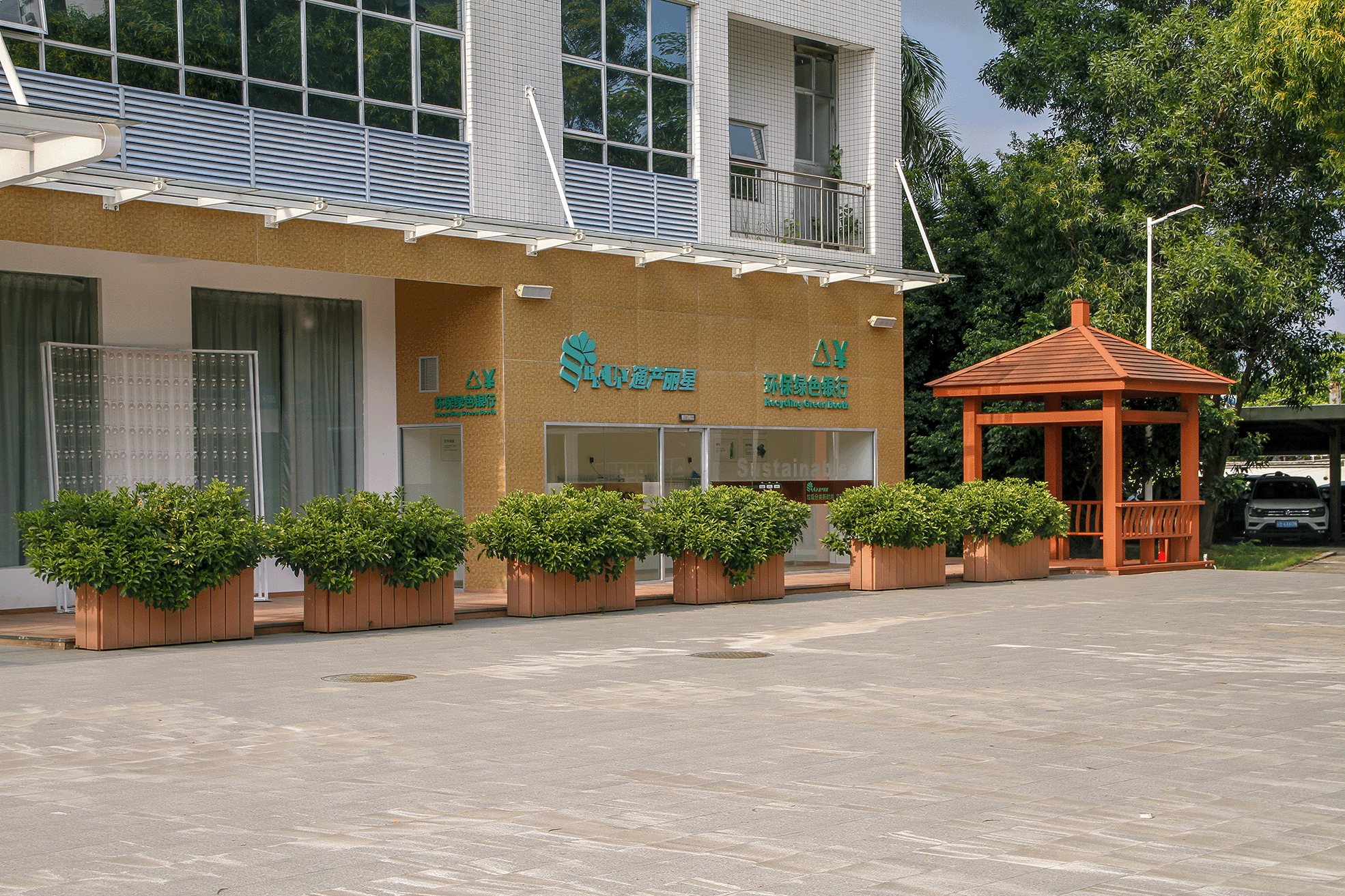

02. Beauty Star Plastic Recycling and Reuse Industrial Base

Project Location and Technology

● Located at No. 1001 Longgang Avenue (Pingdi Section), Longgang District, Shenzhen, Guangdong Province, the project covers an area of approximately 2,500 square meters. It is China's first demonstration base themed around carbon neutrality, integrating industrial on-site operations, science education, and technological experience.

● The park utilizes distributed photovoltaic power generation, a reclaimed water reuse system, energy-saving equipment, and vertical greening to enhance carbon sequestration capacity. It showcases the full industrial process of plastic recycling—from sorting, crushing, washing, and melting to regeneration and granulation—through physical and chemical treatment demonstrations. Leveraging blockchain, IoT, and big data technologies, the park has established a "one bag, one code" tracking system that enables full carbon footprint visualization.

Technical Advantages and Achievements

● The project pioneers the "Front Hall–Back Factory" model, seamlessly integrating science education with real industrial production to provide an immersive circular economy experience. Through technologies such as AI, VR, and blockchain, it transforms abstract low-carbon concepts into tangible, interactive experiences.

● By combining solar power generation, reclaimed water reuse, energy-efficient equipment, and ecological greening, the base achieves low-carbon operations. Blockchain technology ensures full transparency of the recycled plastics' life-cycle data, supporting quantified carbon reduction accounting. The facility recycles over 3,000 tons of renewable plastics annually, reducing dependence on petroleum-based raw materials and lowering the company's overall carbon emission intensity to 28%–38% of the industry average. The "Green Environmental Bank" system further encourages public participation in plastic recycling by offering cashback incentives through QR code scanning.

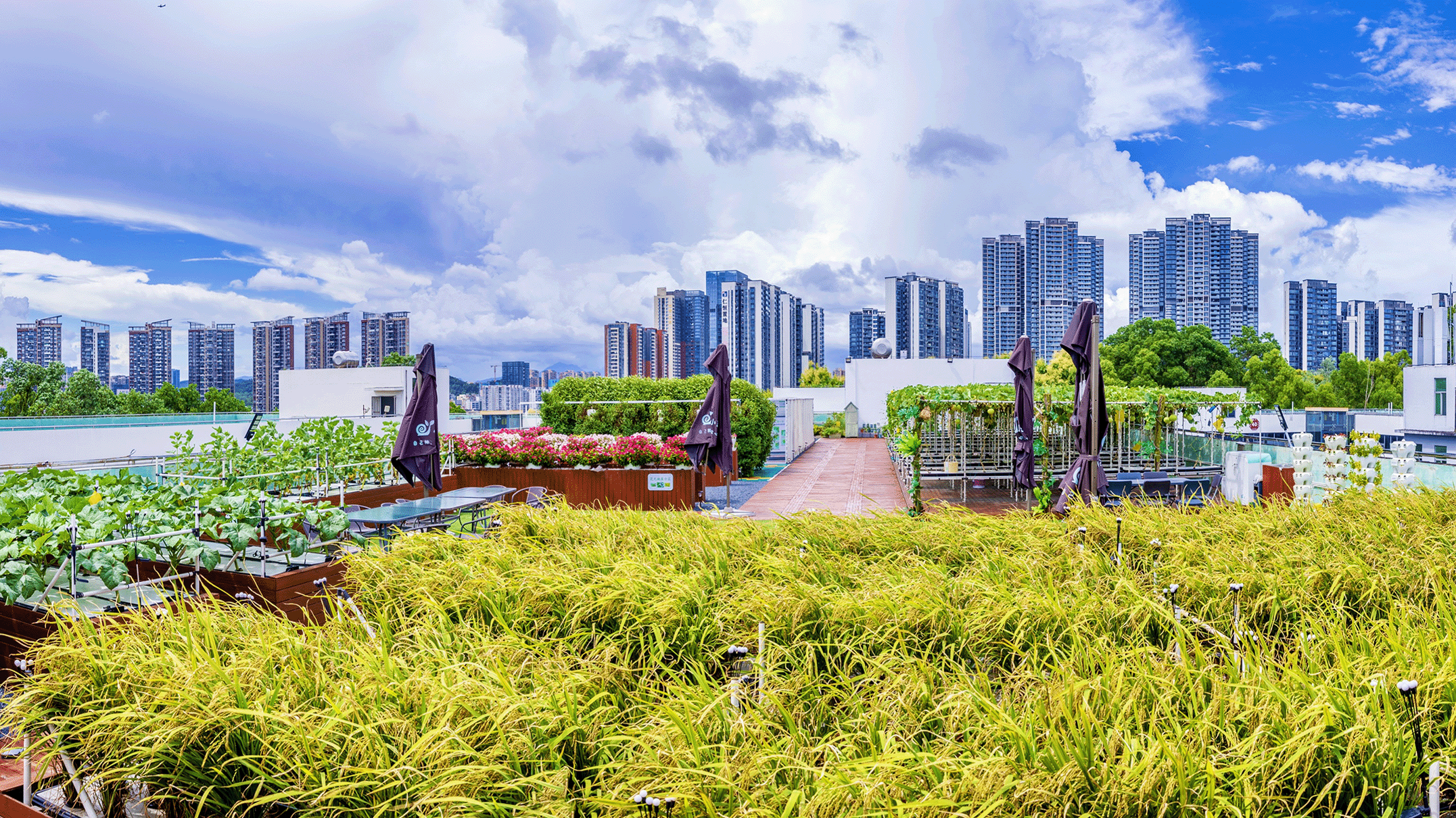

03. Urban Micro-Agriculture Vertical Edible Landscaping Zero-Carbon Project

Project Location and Technology

● Located on the rooftop of Building 37 in Dayun Software Town, Yuanshan Subdistrict, Longgang District, Shenzhen, the project adopts a proprietary soilless vertical cultivation technology combined with an AI-based Internet of Things (IoT) system developed by HZO Bio. It transforms idle urban rooftops—non-arable spaces—into productive planting areas, with a total area exceeding 1,000 square meters.

Technical Advantages and Achievements

● Three-Dimensional Planting Model: The vertical planting system achieves output efficiency far exceeding that of traditional flat farmland, producing 28.6 tons of vegetables and fruits annually and creating an "aerial low-carbon agricultural zone."

● Carbon Reduction Measures: No land reclamation is required, avoiding disturbance to soil carbon storage. Water savings exceed 90%, reducing carbon emissions from irrigation and water treatment. Precision fertilization with nutrient recycling minimizes fertilizer use and the emissions associated with its production and transport. The entire operation runs on low energy consumption, without the need for large-scale agricultural machinery.

● Carbon Sink Capacity: The plant system achieves an annual carbon reduction of 61.6 tons—equivalent to saving over 94,000 kWh of electricity—effectively offsetting the company's annual operational power consumption and achieving a "zero-carbon" target.

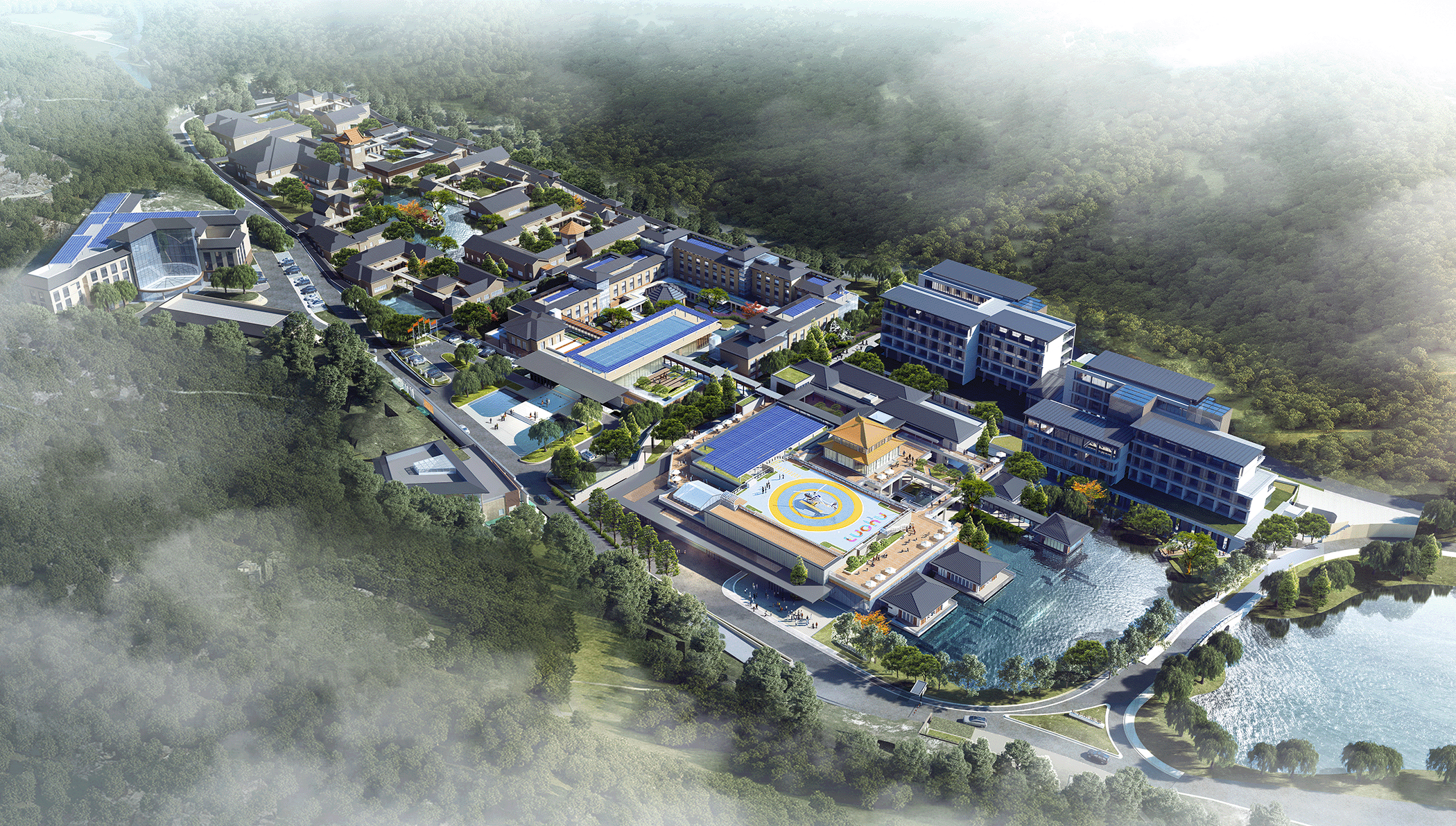

04. Shenzhen Yinhu Conference Center Near-Zero Carbon Building Complex Demonstration Project

Project Location and Technology

● Located at No. 38 Yinhu Road, Qingshuihe Subdistrict, Luohu District, Shenzhen (Shenzhen Yinhu Conference Center).

● The project integrates multiple low-carbon energy technologies into a unified smart management system. The distributed photovoltaic system generates approximately 600,000 kWh annually, with an additional 100,000 kWh from rooftop panels and 47,900 kWh from photovoltaic carports and landscape installations. A 100 kW / 215 kWh energy storage system and a 480 kW ultra-fast charging station are installed, along with V2G (vehicle-to-grid) chargers. A 50 kW SOFC (Solid Oxide Fuel Cell) system generates about 400,000 kWh of electricity per year and supplies 3,000 tons of 60°C hot water, achieving a combined heat and power (CHP) efficiency exceeding 90%.

● The "cloud–edge–device" integrated platform enables coordinated control across photovoltaics, energy storage, charging, and air conditioning systems. A carbon management platform monitors energy consumption and emissions, supporting operational optimization and carbon footprint accounting. Through air-conditioning system optimization, intelligent lighting control, and transformer replacement, the facility achieves annual electricity savings of 290,000 kWh, contributing to its transformation into a high-efficiency, near-zero-carbon complex.

Technical Advantages and Achievements

● The photovoltaic, energy storage, fuel cell, and charging systems operate collaboratively, forming a closed loop of "generation–storage–consumption–feedback."

● The SOFC (Solid Oxide Fuel Cell) system achieves a combined heat and power efficiency exceeding 90%, significantly higher than traditional separate-generation models (approximately 50%–70%).

● The EMS (Energy Management System) enables three-tier coordinated control at the device, system, and regional levels, optimizing energy scheduling and utilization.

● Photovoltaic tiles and PV-integrated landscape features combine power generation with architectural aesthetics, reducing embedded carbon emissions.

● The project achieves an annual carbon reduction of 793 tons, with a renewable energy utilization rate of 9%. The photovoltaic system generates 747,900 kWh annually (around 15% of total electricity consumption), and the SOFC system produces 400,000 kWh per year. The integrated system retrofit delivers annual power savings of 290,000 kWh, equivalent to reducing standard coal consumption by 90 tons per year. Additionally, the SOFC system supplies 3,000 tons of hot water annually, replacing traditional gas boilers and further cutting fossil fuel use.

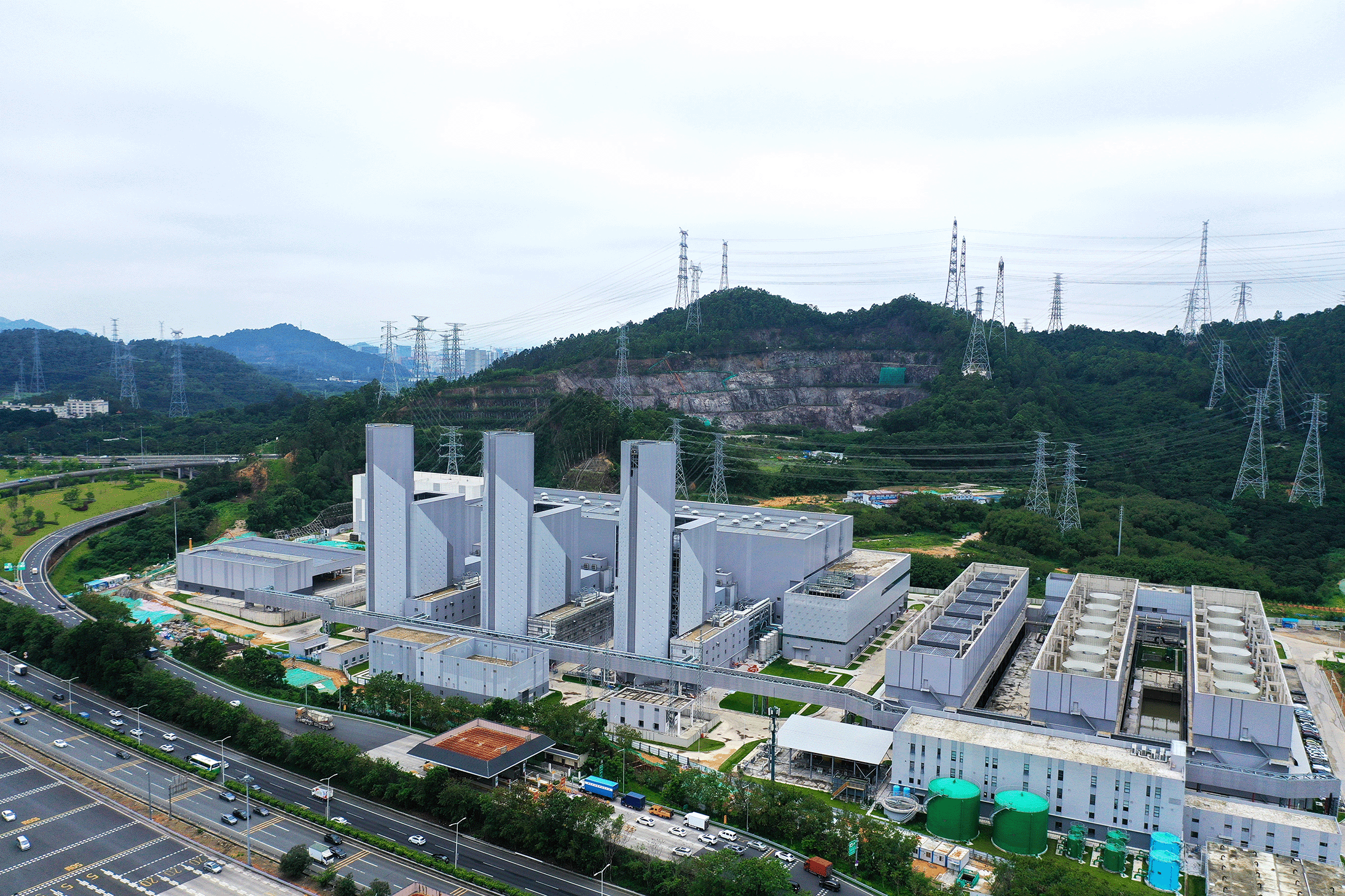

05. Shenzhen Energy Guangming Gas Turbine Power Plant Phase I Project (Shenzhen Energy Guangming Power Base)

Project Location and Technology

● Located on the west side of the Nanguang Expressway in Tianliao and Yulu communities, Yutang Subdistrict, Guangming District, Shenzhen, the project is part of the Phase I Shenzhen Guangming Gas Power Plant (Shenzhen Energy Guangming Power Base).

● Centered on an intelligent control and integrated management system, it features the world's highest-grade (Class H) gas–steam combined-cycle generator units. The project integrates hyper-converged architecture, distributed computing and storage, high-definition surveillance, and robotic inspection, enabling 24/7 intelligent monitoring and management.

● It also develops key technologies for new file formats, enhancing data reliability, transmission stability, and monitoring precision across the entire operation.

Technical Advantages and Achievements

● The hyper-converged architecture and distributed computing system enhance response speed and data processing efficiency. Combining robotic dogs with high-definition cameras, the facility performs multi-sensor integrated inspections, achieving unmanned, high-precision monitoring.

● A fully intelligent management system covers all operational stages—monitoring, control, safety, and maintenance—minimizing human intervention. The intelligent fault recording and waveform analysis system improves data reliability through a new, high-compatibility file format that reduces data loss risk, while fault detection and analysis response time is shortened by 30%, boosting monitoring efficiency.

● The waste heat recovery system saves approximately 5,000 tons of standard coal annually, cutting CO₂ emissions by 12,000 tons. Additionally, sponge city design measures enable 85% rainwater runoff control, reducing the risk of flooding by 70%, and enhancing the plant's environmental resilience.

06. Shenzhen Jingneng Industrial Park Green and Low-Carbon and Intelligent Upgrade Project

Project Location and Technology

● Located at No. 3 Baolong 2nd Road, Baolong Subdistrict, Longgang District, Shenzhen, within the Jingneng Technology Environmental Industrial Park, the project features a comprehensive low-carbon smart energy system.

● A rooftop photovoltaic system covers approximately 61,000 m², with 2,340 solar panels and a total grid-connected capacity of 1,357.2 kW, generating an estimated 1.3 million kWh of electricity annually. Additionally, a 1 MW / 2 MWh energy storage facility has been built, providing around 3,600 kWh of daily charge and discharge, with a first-year discharge of 1.188 million kWh and an expected 10-year cumulative discharge of 10.2 million kWh.

● The site also includes 29 hybrid charging spaces, equipped with high-power DC chargers, superchargers, and AC chargers, alongside a 60 m² perovskite photovoltaic canopy with a grid capacity of 9.36 kW and an annual generation of 9,300 kWh.

● The low-carbon intelligent system integrates DC distribution, a smart cloud platform, building carbon monitoring and management, an energy microgrid, and a virtual power plant (VPP)—forming a unified, efficient, and digitalized green energy ecosystem.

Technical Advantages and Achievements

● The photovoltaic system makes full use of rooftop space, featuring industry-leading installed capacity and power generation efficiency. The high-capacity energy storage system stabilizes solar output and enhances power supply reliability. Multiple types of charging piles support fast charging, while the perovskite photovoltaic canopy provides both power generation and shading functions.

● The smart cloud platform integrates carbon monitoring, energy microgrid, and virtual power plant (VPP) functions, enabling integrated "generation–grid–load–storage" coordination and control for optimized energy management.

● The system generates 1.3 million kWh of electricity annually, with a 10-year cumulative energy storage discharge of 10.2 million kWh, reducing fossil fuel consumption by approximately 3,200 tons of standard coal and cutting CO₂ emissions by about 1,000 tons per year. It supports 29 EV charging spaces, serving over 100,000 electric vehicles annually, while the photovoltaic canopy produces 9,300 kWh per year, meeting part of the site's charging demand.

07. Solid Oxide Fuel Cell Power Generation Project in the East Campus of Guangming District People's Hospital

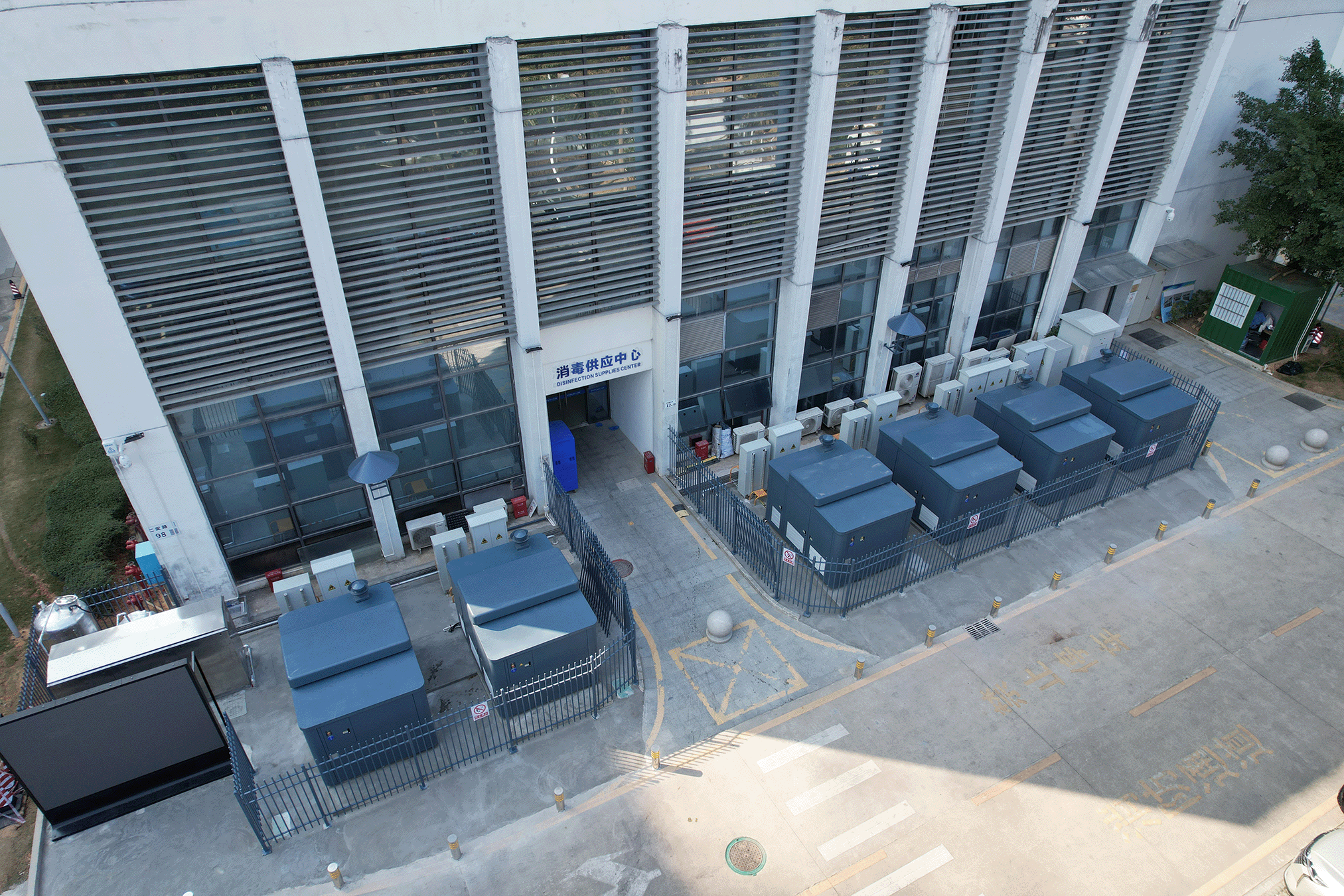

Project Location and Technology

● Located at No. 39 Huaxia Road, Guangming District, Shenzhen, Guangdong Province, the project adopts Solid Oxide Fuel Cell (SOFC) technology to build a natural gas–based distributed combined heat and power (CHP) system.

● With a total installed capacity of 300 kW, consisting of six 50 kW units, the system includes SOFC modules and supporting facilities for water, electricity, and gas connections. Designed for 24-hour grid-connected operation, it runs approximately 8,000 hours per year, generating around 2.4 million kWh of electricity annually. Occupying an area of about 180 m², the project is invested by Shenzhen Gas Group, constructed and operated by Shenzhen Gas Clean Energy Company, and equipped with fuel cell systems supplied by Shenzhen Sanhuan Technology.

Technical Advantages and Achievements

● The project adopts Solid Oxide Fuel Cell (SOFC) technology, which directly converts chemical energy into electrical energy through a solid oxide electrolyte.

● High Power Generation Efficiency: The system achieves an individual electrical efficiency of up to 65%, with a combined cooling, heating, and power efficiency exceeding 85%.

● Green and Low-Carbon: Operates with no vibration or noise (<45 dB) and produces no NOx or SOx emissions.

● Fuel Flexibility: Compatible with natural gas, biogas, hydrogen, and syngas.

● Wide Application: Suitable for hospitals, data centers, and distributed power stations, among other scenarios.

● Domestic Breakthroughs: China's first commercial 50 kW SOFC project and the largest domestic installation at 300 kW.

● High operational stability: 7,000+ hours of continuous operation with a power generation efficiency of 64% (20% higher than traditional gas-fired generation).

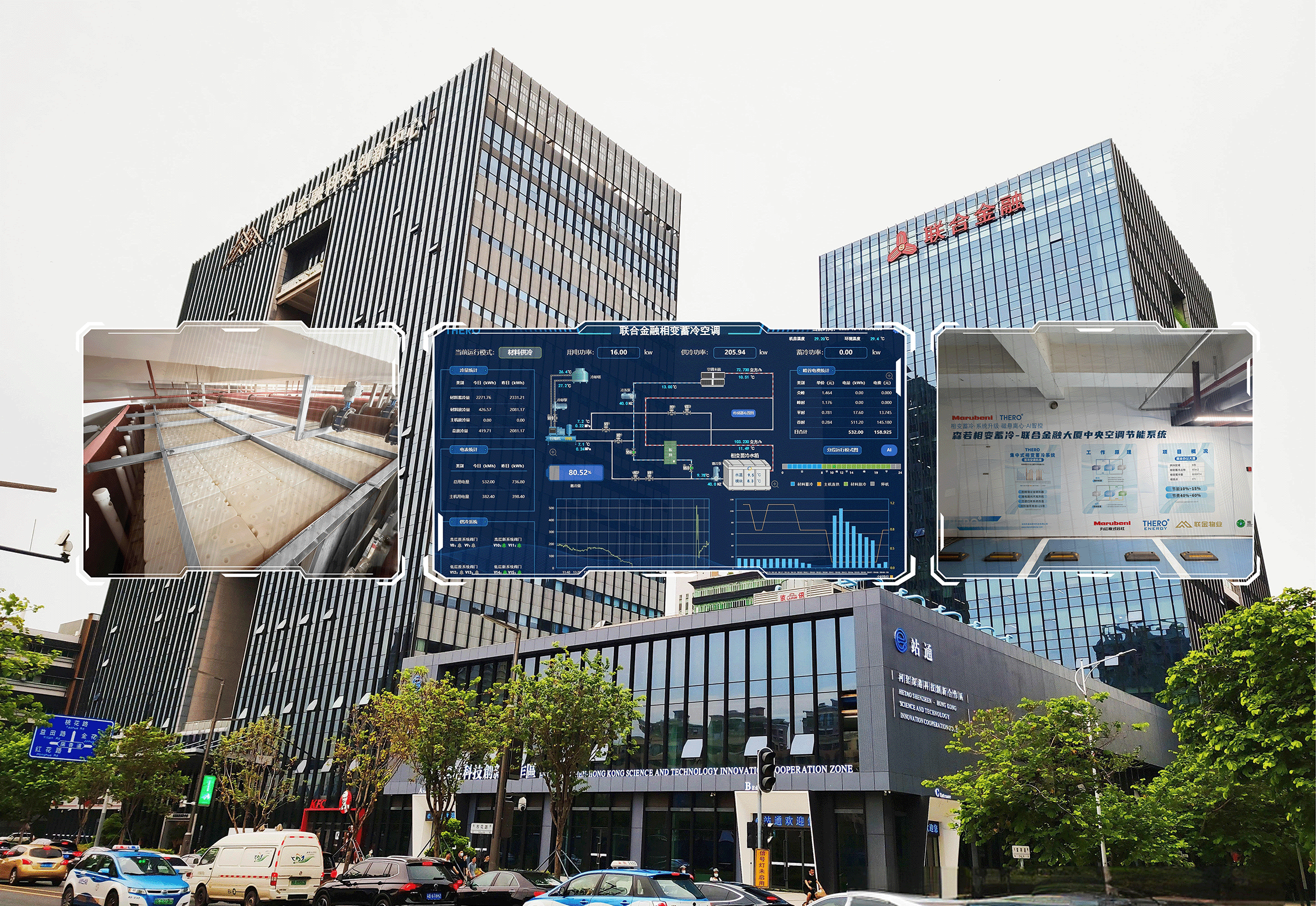

08. THERO Microcrystalline PCM - Central Air Conditioning AI Smart Control Low-Carbon Retrofit Project (Shenzhen United Financial Building)

Project Location and Technology

● Located at No. 1 Shihua Road, Futian Free Trade Zone, Shenzhen, inside the United Financial Building, the phase-change cold storage plant is situated in the southeast corner of the second basement level, utilizing about 100 m² of idle non-parking space (with the cold storage tank occupying 40 m²).

● The system adopts a polymer + microcrystalline 8°C phase-change material, solving the common technical issues of thickening and phase separation found in traditional materials. The material has a latent heat capacity of 210 kJ/L, is certified by TÜV Rheinland, and shows less than 10% latent heat degradation after 10,000 cycles, maintaining its appearance and ensuring a service life of over 20 years. With a cold storage density of 12.7 RTH/m³, the storage tank's volume is only one-fifth that of conventional chilled-water storage systems.

● Connected in parallel with the original chilled-water system, the installation requires no major pipe modifications or system shutdowns, making it ideal for retrofitting older buildings. It stores cooling energy during off-peak nighttime hours and releases it during peak daytime hours, reducing peak load demand. Combined with a high-efficiency magnetic levitation chiller and an AI intelligent control system, it enables dynamic optimization of energy use.

Technical Advantages and Achievements

● The system uses food-grade, non-toxic, and non-corrosive materials that undergo purely physical phase changes with no risk of combustion or explosion. It is recyclable and biodegradable, avoiding secondary pollution associated with chemical batteries. Featuring high stability, its performance degradation remains below 10% after 10,000 cycles, aligning with the entire life cycle of the building.

● With high-density cold storage technology, it achieves a storage capacity of 12.7 RTH/m³, delivering 800 RTH of cooling with just a 40 m² tank. The modular parallel connection design allows for quick, low-cost retrofitting, significantly shortening construction time.

● In terms of economic performance, five months of operational testing verified an 18% energy-saving rate, a 56% reduction in costs, and an off-peak electricity utilization rate exceeding 65%, creating a high-efficiency, low-investment, high-return green energy storage solution.

09. Duckbill Digital-Intelligent Green Energy Transportation Center

Project Location and Technology

● The South China regional headquarters is located at 15/F, Building B, Haizhi Health Industrial Park, 2028 Shenyen Road, Yantian District, Shenzhen. The company's domestic service network spans major ports including Shanghai, Ningbo, Shenzhen, Guangzhou, Qingdao, Tianjin, and Lianyungang. Its overseas headquarters is in Singapore, with operations already launched in Vietnam and Semarang, and network expansion underway in Thailand, Malaysia, Cambodia, and Egypt.

● Through intelligent vehicle networking and a digital logistics platform, the company integrates transportation capacity resources to achieve fully transparent and digitalized end-to-end management. It operates a fleet of over 3,500 container transport vehicles, covering major domestic ports, inland terminals, and Southeast Asian routes. Within Shenzhen, the Comprehensive Bonded Zone Modern Logistics Park and Yantian Port Cold Chain Industrial Park have already deployed 23 charging piles, forming a pure-electric green logistics network centered on foreign trade container services in the Pearl River Delta. By integrating customs clearance and maritime agency services, the company provides end-to-end logistics solutions from origin to destination.

Technical Advantages and Achievements

● Through intelligent scheduling and dynamic optimization, the digital logistics platform breaks down information silos, enabling high-efficiency matching of transportation resources and significantly improving logistics performance. Managing a fleet of over 3,500 container trucks, the company achieves industry-leading economies of scale. The coordination between electric container trucks and the charging network establishes a replicable green transportation model.

● In 2024, digitalized management reduced fuel consumption by an amount equivalent to planting 2.3811 million trees, cutting CO₂ emissions by 42,869 tons.

● Intelligent dispatching improved transport efficiency by over 20% and reduced operational costs by 15%–20%, demonstrating the strong economic and environmental value of digital transformation in logistics.

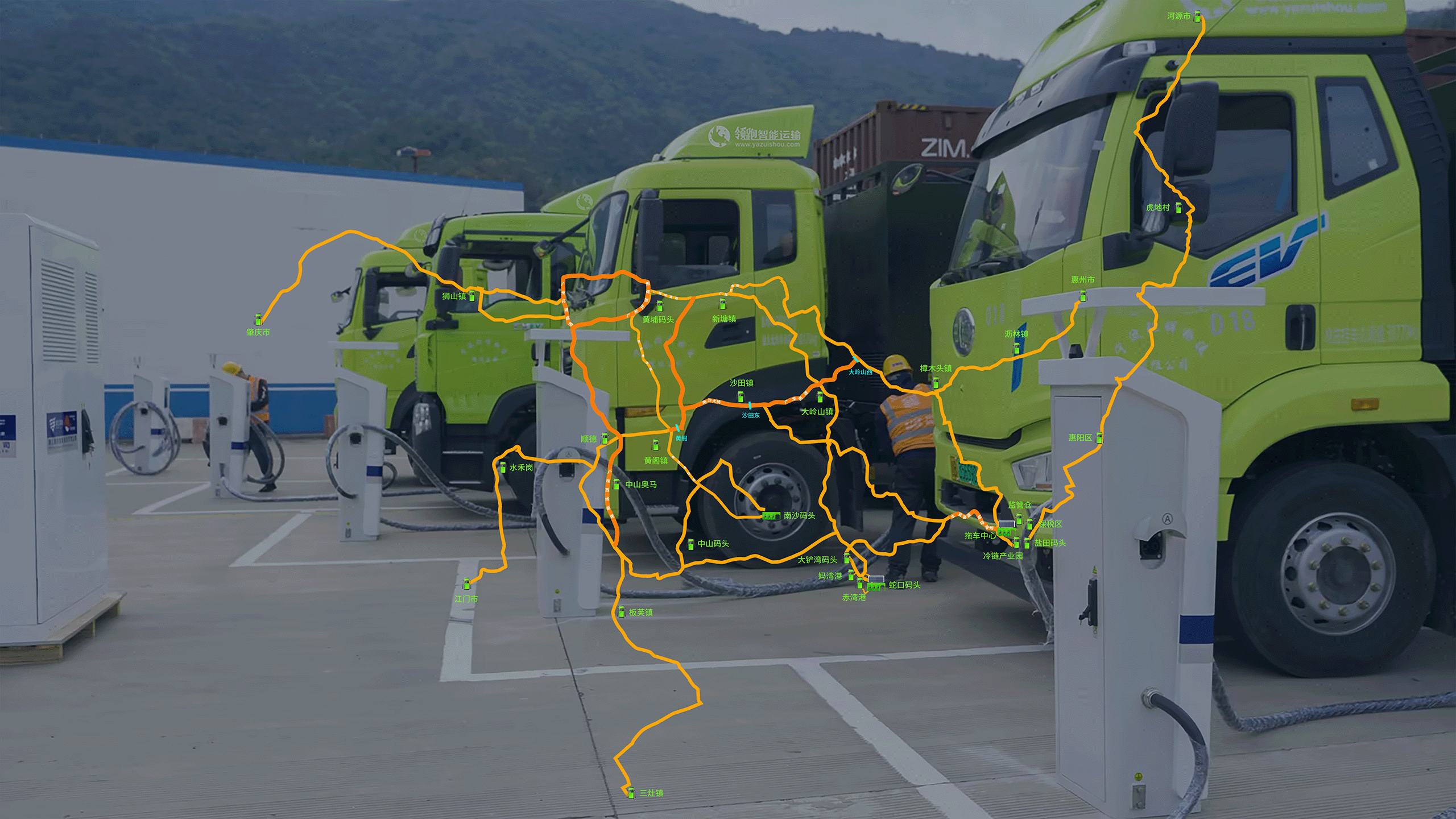

10. Newhappiness Logistics • Transportation-energy Integrated Zero-Carbon Freight Corridor

Project Location and Technology

● Located at 15/F, Building B, Haizhi Cloud Valley, 2094 Shenyen Road, Yantian District, Shenzhen, and No. 26 Xiaba New Village, Xikeng Community, Yuanshan Subdistrict, Longgang District, Shenzhen, the project establishes the Greater Bay Area's first zero-carbon heavy-duty truck fleet, planned to expand to over 400 electric container trucks, replacing traditional diesel-powered vehicles.

● The first batch of 10 trucks was launched in January 2025 and has already accumulated over 620,000 kilometers of operation. The project also operates the region's first megawatt-level ultra-fast charging station dedicated to heavy-duty trucks, supporting high-power rapid charging to ensure efficient fleet operations.

Technical Advantages and Achievements

● The large-scale adoption of electric heavy-duty trucks achieves full electrification of land transport. The megawatt-level ultra-fast charging technology significantly shortens charging time, meeting the demands of high-frequency, heavy-load logistics, while the coordinated operation of electric trucks and ultra-fast charging stations eliminates intermediate emissions from refueling and fuel transport.

● Each electric heavy truck reduces carbon emissions by approximately 118.2 tons per year, and once the 400-truck zero-carbon fleet is completed by 2027, total annual carbon reduction will reach 47,000 tons. The fleet also achieves zero emissions of NOx, particulate matter, SOx, and other volatile organic pollutants, cutting total pollutant emissions by over 50 tons per year.

● The energy cost difference between electricity and diesel reduces operating costs by 0.8–1 RMB per kilometer, meaning each truck traveling 100,000 km per year saves 80,000–100,000 RMB. For the full 400-truck fleet, this results in annual savings exceeding 32 million RMB. The project is projected to generate over 200 million RMB in revenue by 2024, while improving transport efficiency by 15%.